A new method for enhancing lead-free ferroelectric materials using mechanical strain, rather than chemical processes, promises to revolutionize the production of essential electronic components. This discovery, led by researchers at the University of Arkansas and collaborators across multiple institutions, could pave the way for safer and more versatile devices, including those designed for implantation in the human body.

The Problem with Lead

Ferroelectric materials are critical for a wide range of applications, including infrared cameras, medical ultrasound, computer memory, and actuators. These materials convert electrical properties into mechanical movement, and vice versa. However, many high-performing ferroelectrics contain lead, a toxic substance that poses environmental and health risks. For over a decade, scientists worldwide have been searching for viable lead-free alternatives.

The challenge lies in maintaining performance without sacrificing safety. Lead-based materials allow precise chemical tuning to optimize their properties at phase boundaries – the points where different crystalline structures meet. Manipulating these boundaries enhances the material’s effectiveness. But chemically tuning lead-free alternatives has proven difficult, as many contain volatile alkaline metals that can evaporate, compromising stability.

A New Approach: Mechanical Strain

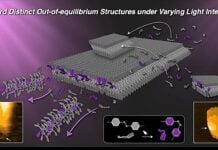

The research team, led by Laurent Bellaiche at the University of Arkansas, discovered that applying mechanical strain – essentially, stretching or compressing the material – can dramatically improve the performance of lead-free sodium niobate (NaNbO3). Unlike chemical tuning, this method avoids the issue of volatile metals.

The team grew a thin film of sodium niobate on a substrate, causing the material to contract and expand as it adapted to the substrate’s structure. This process created strain, forcing the material’s atoms into different arrangements. To the researchers’ surprise, the strain induced three different phases simultaneously, maximizing the material’s useful properties by creating more phase boundaries.

“What is quite remarkable with sodium niobate is if you change the length a little bit, the phases change a lot,” Bellaiche explained. The discovery challenges conventional expectations; researchers anticipated a transition from one phase to another, not the simultaneous existence of three.

Why This Matters

The implications of this breakthrough are significant. Lead-free ferroelectrics enhanced by strain could unlock new possibilities for smaller, more efficient, and safer electronic components. The ability to avoid toxic materials is particularly crucial for devices intended for implantation in humans, such as medical sensors and micro-actuators.

Ferroelectric materials possess unique properties that make them valuable in diverse applications:

- Electrical Polarization: They maintain a reversed electrical charge even after the power is removed, making them ideal for capacitors.

- Piezoelectricity: They generate electricity in response to mechanical stress and vice versa, useful in sonar, fire sensors, and inkjet printer actuators.

Future Directions

The experiments were conducted at room temperature. The next step will be to determine if sodium niobate responds to strain in the same way at extreme temperatures, ranging from -270°C to 1,000°C. This is crucial for expanding the material’s applicability to a wider range of environments.

The research, published in Nature Communications, involved collaboration from North Carolina State University, Cornell University, Drexel University, Stanford University, Pennsylvania State University, Argonne National Laboratory, and Oak Ridge National Laboratory.

This breakthrough represents a major step toward safer and more sustainable electronics, with the potential to transform industries from medical technology to consumer devices. By harnessing the power of mechanical strain, scientists have opened a new path toward high-performance, lead-free ferroelectrics